Advanced Food Tracking and Packaging Will Save Lives and Cut Waste

About 600 million people suffer

food poisoning every year, according to the World Health Organization,

and 420,000 die. When an outbreak occurs, investigators can spend days

or weeks tracking its source. Meanwhile more people can sicken, and

massive amounts of uncontaminated food may be discarded along with the

tainted items. Finding the source can be slow work because food travels a

complex path from farm to table, and the records of those journeys are

kept in local systems that often do not communicate with one another.

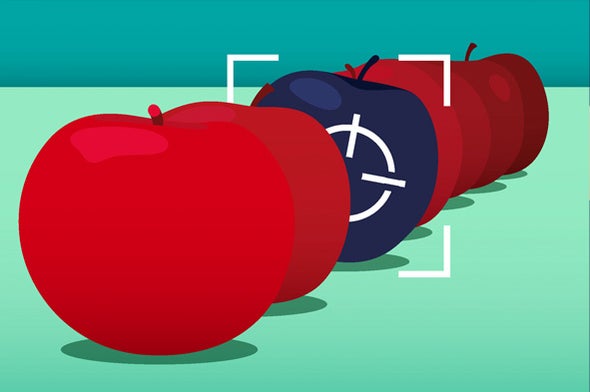

Together a pair of technologies could reduce both food poisoning and food waste. The first, an innovative application of blockchain technology (better known for managing virtual currency), is beginning to solve the traceability problem. Enhanced food packaging, meanwhile, is providing new ways to determine whether foods have been stored at proper temperatures and whether they might have begun to spoil.

Blockchain is a decentralized accounting system in which entries are recorded in sequence in multiple identical “ledgers” stored on computers in multiple locations. This redundancy makes tampering with any one ledger futile, creating a highly trusted record of transactions. A blockchain-based cloud platform developed for the food industry—IBM Food Trust—is already employed by major food sellers. (One of us—Meyerson—is affiliated with IBM.)

By integrating growers, distributors and retailers on a common blockchain, Food Trust creates a trusted record of a given food’s path through the end-to-end supply chain. In a test using the technology, Walmart traced the origin of a “contaminated” item in seconds; with the standard mix of written and digital records, this would have taken days. With this capability, retailers and restaurants can remove a contaminated item from circulation virtually immediately and destroy only stock that came from the same source (say, a particular grower of romaine lettuce) instead of wasting entire national stocks of the item. Many food-business giants—Walmart, Carrefour, Sam’s Club, Albertsons Companies, Smithfield Foods, BeefChain, Wakefern Food (ShopRite’s parent) and Topco Associates (a group purchasing organization)—have joined the IBM Food Trust. Other organizations have also introduced blockchain technology for enhancing traceability.

Cost remains a roadblock to the ubiquitous use of sensors. Still, the food industry’s need to ensure food safety and limit waste is propelling this technology and blockchain forward.

Together a pair of technologies could reduce both food poisoning and food waste. The first, an innovative application of blockchain technology (better known for managing virtual currency), is beginning to solve the traceability problem. Enhanced food packaging, meanwhile, is providing new ways to determine whether foods have been stored at proper temperatures and whether they might have begun to spoil.

Blockchain is a decentralized accounting system in which entries are recorded in sequence in multiple identical “ledgers” stored on computers in multiple locations. This redundancy makes tampering with any one ledger futile, creating a highly trusted record of transactions. A blockchain-based cloud platform developed for the food industry—IBM Food Trust—is already employed by major food sellers. (One of us—Meyerson—is affiliated with IBM.)

By integrating growers, distributors and retailers on a common blockchain, Food Trust creates a trusted record of a given food’s path through the end-to-end supply chain. In a test using the technology, Walmart traced the origin of a “contaminated” item in seconds; with the standard mix of written and digital records, this would have taken days. With this capability, retailers and restaurants can remove a contaminated item from circulation virtually immediately and destroy only stock that came from the same source (say, a particular grower of romaine lettuce) instead of wasting entire national stocks of the item. Many food-business giants—Walmart, Carrefour, Sam’s Club, Albertsons Companies, Smithfield Foods, BeefChain, Wakefern Food (ShopRite’s parent) and Topco Associates (a group purchasing organization)—have joined the IBM Food Trust. Other organizations have also introduced blockchain technology for enhancing traceability.

Cost remains a roadblock to the ubiquitous use of sensors. Still, the food industry’s need to ensure food safety and limit waste is propelling this technology and blockchain forward.

No comments